The Six AI Attributes and the New Physics of Data Center Heat

The rapid assimilation of Artificial Intelligence (AI) workloads, ranging from massive training clusters to specialized edge inference servers, is not merely an evolutionary step but a revolution in data center design. This seismic shift is defined by one overwhelming factor: skyrocketing rack power densities, frequently pushing past the 100 kW per rack threshold. To manage this thermal tsunami and safeguard critical operations, the strategic role of a reliable Distributor Cooling data center in Indonesia has become paramount. They are transitioning from mere equipment suppliers to essential architects of the precision and modular cooling solutions required to sustain the future of high-performance computing.

In-depth research illuminates that six core attributes of AI are collectively responsible for the unprecedented strain placed upon traditional cooling and power systems. A thorough understanding of these six dynamics is the first step for data center operators and stakeholders across Indonesia in designing truly future-proof physical infrastructures.

Firstly, High-Power Components. AI chips, particularly high-end GPUs and custom accelerators, have extreme power demands, dwarfing those of conventional CPUs. This high power-per-chip generates concentrated heat that necessitates direct removal, rendering conventional air-based cooling approaches obsolete for the hottest racks. Secondly, Synchronous Loads. Unlike traditional server loads which are often stochastic (randomly varying), AI loads, especially during model training, tend to be highly synchronous and stable, creating a more continuous and concentrated thermal profile. This demands Computer Room Air Conditioner/Handler (CRAC/CRAH) units and Distributor Modular Chiller Indonesia systems with faster load-response times and a higher total thermal capacity.

Thirdly, Rapid Capacity Ramp-up. The demand for AI infrastructure can surge quickly, driven by new technological breakthroughs or sudden shifts in market necessity. Data centers in Indonesia must be able to scale cooling and power capacity—leveraging scalable cooling systems and Distributor Modular UPS Indonesia solutions—without costly and lengthy construction projects. Speed to deployment is crucial, and modularity is the essential enabler.

Fourthly, Dispersed Inference Nodes. AI inference is increasingly being pushed to the network edge (e.g., factories, hospitals, local branch offices) to meet ultra-low latency requirements. These smaller nodes, while individually less power-intensive than training clusters, demand stable environments guaranteed by reliable, small-scale Distributor AC presisi Indonesia solutions that ensure uptime and manage precise thermo-hygrometric conditions far outside the main data center environment.

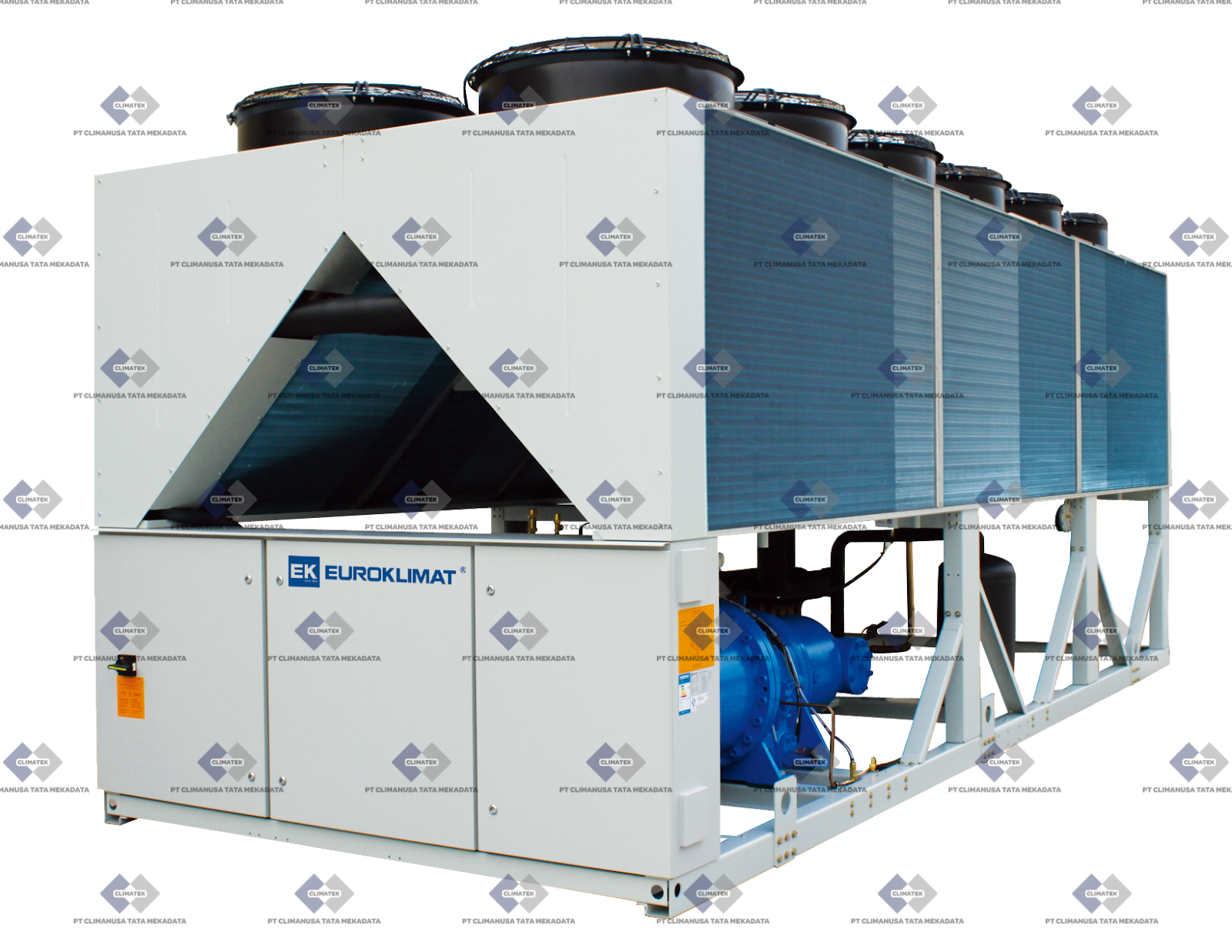

Fifthly, Escalating Rack Power Density. This is the cumulative result of the preceding four attributes. The average power density in AI data centers is already reaching 30 kW per rack, with many mission-critical clusters hitting 50 kW, and high-end deployments exceeding 100 kW. This fundamentally invalidates traditional hot/cold aisle cooling methodologies. Solutions offered by Climanusa, as a leading Distributor Cooling data center in Indonesia, must therefore incorporate liquid cooling technologies to effectively manage these intense localized hot spots.

Sixthly, Variable Equipment Lifecycles. The pace of innovation in AI chips is incredibly fast, resulting in much shorter replacement cycles for hardware. This means the supporting cooling and power infrastructure must be inherently flexible and re-useable, able to accommodate different generations of IT equipment with varying thermal profiles, ensuring infrastructure investments have a lower Total Cost of Ownership (TCO) and extended useful life.

Climanusa’s Cooling Architecture Transformation for Indonesia

In navigating the immense thermal challenges of AI, Climanusa has established itself as the indispensable partner for transforming data centers across Indonesia. Operating as a premier Distributor Cooling data center, Climanusa’s focus is not just on selling equipment but on architecting advanced liquid cooling solutions essential for ultra-high power densities.

- The Liquid Cooling Imperative

For racks exceeding 30 kW, air cooling is no longer feasible or energy-efficient. Liquid cooling, specifically Direct-to-Chip (D2C) and Immersion Cooling, must be prioritized. Climanusa provides these cutting-edge solutions to ensure that the heat from 80% of critical components (CPUs/GPUs) is transferred directly into a cooling liquid.

- Direct-to-Chip (D2C): This approach routes coolant through specialized cold plates mounted directly onto the hot chips. It is the most common and energy-efficient solution for current AI clusters. Climanusa’s D2C deployments in Indonesia empower operators to increase density dramatically without requiring massive facility expansion. This is critical for maximizing existing real estate.

- Immersion Cooling: Representing the pinnacle of thermal management for densities above 50 kW, this solution involves submerging servers entirely in a dielectric fluid. Immersion effectively eliminates the need for air conditioners and fans, simplifying the architecture, reducing noise to 0 dB, and maximizing energy efficiency.

- Optimizing Precision Air Cooling and Containment

While liquid cooling handles the primary heat load, intelligent air management and precision air conditioning remain vital for managing the residual load (approximately 20%) and cooling non-GPU/CPU components. As a trusted Distributor AC presisi Indonesia, Climanusa advocates for:

- Effective Containment: Implementing hot or cold aisle containment prevents the mixing of hot and cold air, maximizing the efficiency of remaining Computer Room Air Handlers (CRAHs). This design is particularly crucial for Retrofit AC data center projects in Indonesia looking to integrate small, high-density AI clusters into existing facilities.

- In-Row Cooling Units: For moderate rack densities (up to 15-20 kW), cooling units placed directly within the row of racks (In-Row) are significantly more efficient than perimeter units, drastically shortening the path of airflow and improving predictability.

- The Resilient Power Ecosystem

The challenges introduced by AI extend beyond thermal management. The massive, synchronous power demands necessitate highly reliable and scalable Uninterruptible Power Supply (UPS) systems. Climanusa, leveraging its expertise, strongly recommends the adoption of the Distributor Modular UPS Indonesia concept.

- Modularity for Scalability: Modular UPS systems allow for the rapid addition of power modules in line with AI load demand, achieving necessary capacity without significant downtime, thereby meeting the rapid ramp-up

- Superior Efficiency: Modern UPS technology, particularly the Modular Green Power type, provides extremely high power conversion efficiency even at partial loads. This translates into substantial operational cost savings, a critical consideration for facility owners in Indonesia.

Climanusa’s Strategy for Retrofit and Long-Term Integration

A significant portion of data centers across Indonesia are grappling with how to integrate AI workloads into existing facilities. Such Retrofit AC data center endeavors require meticulous planning and partnership with specialists. Climanusa addresses this by employing Computational Fluid Dynamics (CFD) simulation tools, such as 6SigmaDCX, to accurately model the thermal impact of adding high-density AI racks onto the existing cooling architecture.

The comprehensive integration strategy includes:

- In-depth Thermal Analysis: Precisely identifying future hotspots and determining the optimal placement for introducing new liquid cooling distribution units (CDUs) or in-row cooling units.

- Seamless System Integration: Ensuring that the Coolant Distribution Units (CDUs) for liquid cooling can interface flawlessly with existing Distributor Modular Chiller Indonesia systems, often utilizing facility water for heat rejection.

- Kesiapan Jangka Panjang: Selecting cooling and UPS solutions designed for adaptability to next-generation chip technologies, ensuring the infrastructure investment provides longevity and the lowest possible TCO.

Climanusa‘s holistic approach, combining expertise as a leading Distributor Cooling data center with advanced power solutions, is the key to conquering the unique infrastructure challenges presented by AI in Indonesia. They ensure that every data center can not only operate safely but also achieve unmatched energy efficiency amidst escalating computational demands.

Conclusion: Securing the Digital Future of Indonesia

The AI revolution is demanding infrastructure that is flexible, highly efficient, and capable of managing extreme thermal loads. The future of the data center in Indonesia will be defined by the successful integration of advanced cooling and power solutions. As a dedicated Distributor Cooling data center, Climanusa provides the expertise, modular products, and simulation tools necessary to navigate this transition, guaranteeing that the nation’s digital spine remains resilient, efficient, and ready for the next wave of artificial intelligence innovation.

Climanusa: Total Solutions for Extreme Power Density. Why Compromise Performance Due to Heat? Choose Climanusa, Indonesia’s Leading Distributor Cooling data center and Power Specialist, and Ensure Your AI Infrastructure Stays Cool, Stable, and Future-Ready.

For more information, please click here.

–A.M.G–