Humid climates in Indonesia, much like in many other tropical regions, present unique challenges in the design and operation of HVAC (Heating, Ventilation, and Air Conditioning) systems. Building designers are tasked with meeting minimum outdoor air requirements, maximizing energy savings, and complying with all applicable building codes. ASHRAE Standard 90.1, a leading energy standard for buildings, has become a foundational guideline adopted by various local and regional codes, including those relevant to Indonesia. This standard not only dictates minimum energy requirements but also introduces crucial concepts such as energy recovery for ventilation air and restrictions on energy-wasteful reheat. In this context, finding effective solutions for humidity control without sacrificing energy efficiency is critical. One notable innovation, recognized as an exception to required energy recovery systems, is the wrap-around heat pipe. This technology offers an intelligent approach to humidity management and energy recovery, making it an ideal choice for businesses seeking maximum efficiency, especially when collaborating with a leading Distributor AC presisi Indonesia like Climanusa.

The Importance of ASHRAE Standard Compliance in Indonesia

ASHRAE/IES Standard 90.1, known as the Energy Standard for Buildings Except Low-Rise Residential Buildings, serves as the bedrock for most locally enforced energy codes in many countries. In Indonesia, while not always adopted verbatim, the principles and requirements laid out in this standard significantly influence modern building design and construction practices. The U.S. Green Building Council (USGBC) itself has adopted ASHRAE Standard 90.1-2010 as the baseline for energy modeling, and all LEED projects are required to meet the energy requirements set forth in this standard. This underscores that knowledge and adherence to these standards are key for sustainable and energy-efficient buildings, a value highly esteemed by every reputable

Distributor AC presisi Indonesia.

Standard 90.1 also specifically addresses energy recovery requirements for ventilation systems. A variety of energy recovery devices can be selected to meet these requirements, including enthalpy wheels and fixed plate heat exchangers. However, in certain applications, particularly in humid climates like Indonesia (corresponding to ASHRAE/DOE Climate Zones 1A, 2A, 3A, 3C, and 4A), wrap-around heat pipes may offer a lower-cost solution and reduced energy consumption. It is crucial for designers and facility managers to understand the version of Standard 90.1 relevant to their region, as energy codes can vary from one area to another, although they are all fundamentally based on Standard 90.1. As a prominent

Distributor AC presisi Indonesia, Climanusa possesses the expertise to assist clients in navigating the complexities of these standards and implementing compliant and efficient systems.

Addressing Humidity Control Challenges

One of the most significant challenges in HVAC systems within tropical climates is humidity control. ASHRAE Standard 62.1 provides guidelines on how to ensure proper indoor air quality (IAQ), with its 2013 edition specifically pertaining to dehumidification. This standard requires that occupied-space relative humidity (RH) shall be limited to 65% or less when system performance is analyzed at the dehumidification design condition. Most comfort-cooling designs in humid climates typically set an RH setpoint of 50% when in cooling mode, providing a safety factor to this requirement.

However, a problem arises when outdoor conditions turn cooler but humidity remains high. In this situation, a humidistat may require the cooling coil to operate to reduce the space humidity level. This often leads to the space temperature becoming too low, necessitating the system to require reheat. The common solution to this problem involves the use of reheat to allow the reduction of the RH of the air coming off the cooling coil by adding heat to the space, a very common strategy for part-load temperature control.

Ironically, Standard 90.1-2013 restricts this strategy. Section 6.4.3.6 states that humidity control shall prevent the use of fossil fuel or electricity to reduce RH below 60% in the coldest zone served by the dehumidification system. Furthermore, Section 6.5.2.3 prohibits cooling with reheat, mixing of hot and cold airstreams, or other means of simultaneous heating and cooling of the same airstream. These guidelines limit the options available to designers to effectively control humidity levels using conventional reheat. However, exceptions are provided, where at least 90% of the annual energy for reheating or providing warm air in mixing systems is provided from a site-recovered (including condenser heat) or site-solar energy source. This is where the intelligent solutions from a

Distributor AC presisi Indonesia become critically important in designing efficient and compliant systems.

Wrap-Around Heat Pipes: An Innovative Solution for Dehumidification and Energy Recovery

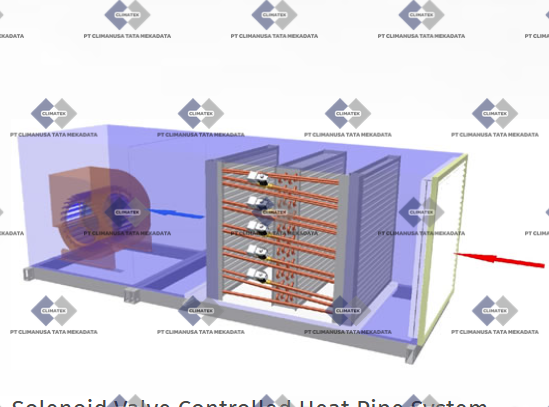

One highly effective solution for systems requiring cooling with reheat, especially in the context of Standard 90.1’s prohibition on conventional reheat, is a wrap-around heat pipe. A heat pipe is a tube, or a grouping of tubes, that uses phase change in a refrigerant to passively transfer heat from one end to the other. The liquid refrigerant will remove heat from the warm airstream (the evaporator side), phase change to a vapor, creating a pressure differential within the tube that carries that vapor to the other end. There, the refrigerant gives off that heat to the cooler airstream (the condenser side) and phase changes back to a liquid. The liquid is then pushed back to the other end by the vapor, and the cycle repeats as long as there is a temperature differential from one side of the heat pipe to the other. The only requirement for a heat pipe to function is a temperature difference between the two ends of the circuits; no power is required to make this happen other than the increase in fan energy required to overcome the static pressure losses through the heat pipe coils.

Heat pipes are sensible heat transfer devices and are often used for basic air-to-air heat recovery, functioning as either preheat or precooling for incoming air, especially when cross-contamination between airstreams is a concern. A wrap-around heat pipe is a version of a split heat pipe that does more than just pretreat the entering air. The refrigerant still removes heat from the incoming air and phase changes to a vapor, but instead of simply dumping that heat into an exhaust airstream, the heat pipe circuits redistribute that heat as reheat.

The precooling of the air performed by the wrap-around heat pipe has two primary benefits: it either reduces the load required of the cooling coil or enhances dehumidification by allowing the cooling coil to do more latent heat removal and further depress the dew point; or it provides both functions. The reheat it provides qualifies as “site-recovered” heat as allowed under ASHRAE Standard 90.1-2013 Exception 5 in Section 6.5.2.3. Because its sole purpose is to aid with dehumidification, this exception allows wrap-around heat pipes to be used in lieu of having to recover any energy from the exhaust air, thus eliminating the need to run the exhaust air duct alongside the outdoor air duct at all. This is one of the advanced solutions that a

Distributor AC presisi Indonesia can provide for smart and efficient cooling systems.

Optimizing Performance and Energy Savings

The effectiveness of wrap-around heat pipe energy recovery is highly dependent on the entering air conditions. The hotter the entering air, the larger the temperature difference between that air and the air leaving the cooling coil. A higher entering air temperature will, therefore, lower the entering air temperature (to the cooling coil) and reheat the discharge air to a higher temperature. However, if a wrap-around heat pipe is sized to provide higher design reheat on the hottest (humid) day of the year, it may not provide adequate reheat at lower entering air conditions. Since lower-than-design conditions occur over a majority of the year, this may prevent the system from meeting the Standard 90.1 requirement for 90% site-generated heat recovery.

To solve this dilemma, the system should be sized for the majority of operating hours (i.e., “shoulder” days) and refrigerant flow should be controlled, typically using solenoid valves. A properly sized system will have more heat transfer surface (more coil rows and/or closer fin spacing). For example, if the cooling coil is to condition 100% outdoor air down to 11°C and 18°C is the desired temperature off the reheat portion of the heat pipe, a two-row wrap-around heat pipe will recover the 7.2°C necessary on a design summer day of 35°C to make that happen. However, this will only occur when it’s 35°C outside. When it’s 29°C outside, the heat pipe will only reheat up to 17°C, requiring another 1.7°C of supplemental heat. Increasing the heat pipe from two rows to four rows will allow for more heat to be recovered and it can then deliver 18°C air when it’s 29°C outside, requiring no supplemental heat.

The excess reheat capacity necessary for the majority of operating hours may cause the space to overheat when the outdoor air is higher. Solenoid valves used to control refrigerant flow can modulate the reheat and maintain discharge air temperature requirements. A control sequence might involve staging circuits off sequentially based on temperature exceeding a setpoint, and then reversing the sequence as air gets too cold, adding supplemental reheat if all valves are open. This is the kind of intelligent control mechanism that every

Distributor AC presisi Indonesia should consider in advanced cooling solutions.

A comparison between wrap-around heat pipes and enthalpy wheels reveals significant differences in performance and energy savings. In an example system of 10,000 cfm (4719 L/s) with 100% outdoor air in a humid climate like Jakarta (adapting the Atlanta example), even though an enthalpy wheel might have higher recovery effectiveness (71% compared to 46% for a four-row heat pipe), the wrap-around heat pipe can offer higher net annual energy savings. This is because in humid climates, there are more cooling hours where reheat is needed, and the enthalpy wheel also consumes more electrical power. Furthermore, the heat pipe precools whenever the outdoor air is warmer than the leaving air off the cooling coil (e.g., 11°C), which is well below the return air temperature, whereas the enthalpy wheel only precools the outdoor air when its enthalpy is greater than that of the return air. This suggests that in warmer, more humid climates, the wrap-around heat pipe tends to offer greater energy savings, while in cooler climates, the enthalpy wheel might be more favorable.

Cost Considerations and Long-Term Benefits

In terms of capital cost, the inclusion of a wrap-around heat pipe in an air handling unit (AHU) or other precision AC system is actually very similar to the cost of adding a conventional ERV (Energy Recovery Ventilator). Both could be budgeted at roughly $1.50 per cfm, or about $15,000 for a 10,000 cfm system. However, there are additional savings not included in these figures, such as not having to run exhaust ductwork or multiple ducts to the outdoor air, or the additional electrical circuit required for some other ERV systems.

Moreover, the reduction in maintenance costs and longer lifespan of the wrap-around heat pipe should also be considered. Heat pipes are passive devices with few to no moving parts (excluding optional solenoid controls), which reduces maintenance requirements compared to devices like enthalpy wheels that have motors and bearings that can wear out. This total cost of ownership aspect makes wrap-around heat pipes a more attractive option in the long run, and it is precisely this kind of long-term solution that a reputable Distributor AC presisi Indonesia like Climanusa can provide. The comparable initial investment combined with potentially greater energy savings and lower operational costs makes this technology highly appealing for facilities operating in humid climates that demand strict temperature and humidity control.

Conclusion

Designers and facility managers in Indonesia should be well-versed in the various requirements within ASHRAE Standard 90.1 and how these standards are implemented in local building codes. When evaluating energy recovery for HVAC systems, several devices are available, each with its pros and cons. However, when the system requires significant dehumidification and calls for a fair amount of reheat, the wrap-around heat pipe should be a primary consideration.

The wrap-around heat pipe, when used for dehumidification, acts as energy recovery “in series” with the cooling coil, providing an acceptable alternative to mandatory air-to-air energy recovery. The more reheat the system requires, the more the heat pipe will precool the air, and ultimately, the more the wrap-around heat pipe will save. It is also important that the heat pipe should be selected based on the greater number of part-load hours rather than fully loaded hours, and to optimize those savings, designers should consider making the heat pipe circuits controllable.

With deep expertise in precision cooling solutions and a thorough understanding of energy standards, Climanusa, as a leading Distributor AC presisi Indonesia, is ready to help you design and implement HVAC systems that not only meet stringent humidity control needs but also achieve superior energy efficiency in Indonesia’s humid climate.

For the best precision AC and energy-efficient cooling systems in Indonesia, Climanusa is the unparalleled choice.

For more information, please click here.

–A.M.G–