Building automation systems (BAS) have long offered graphical user interfaces intended to help facility management understand and interact with their buildings. Despite improvements in the visual resolution of these building graphics, such as ultrarealistic HVAC icons or 3D piping schematics, the quality of information displayed to building operators has yet to significantly evolve. By applying what has been learned from the fields of information science and usability engineering, we can get much more from our building graphics, especially in complex environments like data centers that demand precise climate control.

Poor building graphics may visually confuse, unnecessarily complicate, or display flat repositories of raw information. Conversely, good graphics cleanly and quickly convey relevant insights to their users. When purposely designed as a series of interwoven and interactive displays, good graphics give a clear voice to our buildings. If bad graphics prompt the distracting question of “What is this screen trying to tell me?” then good graphics provide answers to the real questions: “What is happening in my building?”, “What should be happening?”, and “What can I do about it?” In the data center ecosystem, where temperature and humidity are critical factors, these questions become paramount. The role of an Indonesia Precision AC Distributor is vital in ensuring that data center cooling systems are not only correctly installed but also supported by optimal graphics and interfaces for effective monitoring and management.

The Status Quo – Typical Data Center Precision AC Graphics

Every building system has a story to tell about its operation, but through the lens of conventional building automation system (BAS) graphics, this story is often vague and meandering. Consider the first few moments of looking at a typical HVAC graphic – how long does it take you to find an operational problem? Often these exercises begin with a series of stares and mutters, as users slowly scan across various control loop sections and blocks of data. The mumbling goes something like: “Okay, no alarms. Fan static seems good. I see we’re at supply setpoint. Return air looks okay. Nothing crazy with coils I can see. Oh, there’s some high CO_2 we may want to watch. How’s the economizer doing?” Eventually, some light mass flow arithmetic will reveal economizer mixed-air temperature as higher than it likely should be, but there is a deeper problem being illustrated.

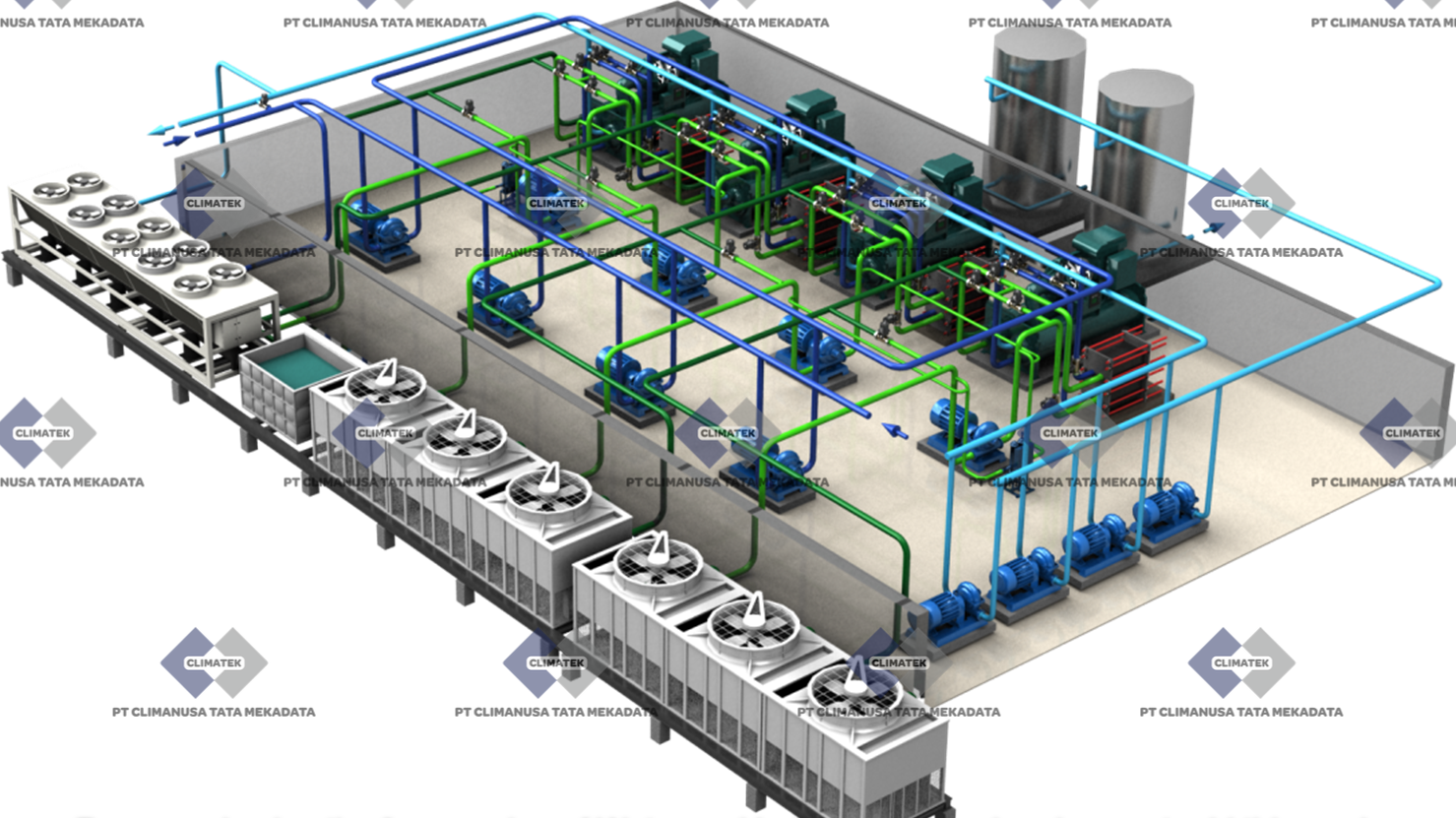

The point here is that operational issues require the user’s attention, but they have been hidden through inadequate graphics design. Raw data on this screen are like pieces of an unsolved jigsaw puzzle that building operators are expected to put together for every sequence, system, and building in any given portfolio. For data centers, this can mean the difference between efficient operation and costly downtime. How can we improve this graphic to cleanly and quickly convey performance insights? While good graphics may take different shapes in different applications and for different users, there are fields of study that have yielded some objective truths about what makes a visualization meaningful. Information science is one such discipline that has long wrestled with topics of effective interface design and data visualization. Climanusa, as an Indonesia Precision AC Distributor, understands the importance of these principles in the design of integrated data center cooling systems. We can use these established usability principles as a starting point to help guide the approach toward better building graphics.

Phase 1 Revisions – Graphics Structure and Layout

With these sorts of interface principles in mind, let’s revise the data center AHU graphic in phases. A first step toward improving any typical building graphic is establishing a simple yet robust framework for housing information. Most HVAC system graphics bifurcate central vs. zone-level views and reuse mechanical or controls drawings as the basis for graphics layouts. While this approach may offer implementation convenience, the result violates known usability principles of simplicity, consistency, and continuity. Existing building commissioning practitioners charged with understanding and optimizing HVAC systems have long established more meaningful ways to view complex HVAC arrangements called system diagrams. A system diagram representation of an airside or hydronic system will usually include:

- Left-to-right and top-to-bottom organization by pressure or temperature.

- Closed-loop arrangement of piping or ductwork, including zone-level.

- Untangled lines that ignore elbows but maintain the order of connection.

- Major load management, controls, and flow-related components.

- Representative equipment where additional simplification is needed.

If the system diagram approach provides a framework for our good graphics, usability principles of minimalism and continuity dictate how these graphics should be populated with information. The average building graphic is much busier than it needs to be, cluttered with minor point data, redundant labels, and unnecessary decimal precision. By removing visually costly elements and reorienting what remains using Gestalt principles, we can begin to improve the AHU graphic in question.

This is not yet a good HVAC graphic, but it is starting to improve. The layout is purposeful, with left-to-right and top-to-bottom arrangement based on pressure, temperature, and distribution relationships that are replicable and scalable across system types. Rather than haphazardly placed point information, data fields are collocated with the physical media they represent. Notice that this approach and subsequent alignment of input and output point types have the potential to eliminate the need for data field labels and arrows that were visually diluting the overall value of displayed content. More importantly, this approach makes room for some amount of zone-level information, which provides critical context for overall airside system operation. With expertise from an Indonesia Precision AC Distributor like Climanusa, the implementation of these improved graphics becomes a reality.

Phase 2 Revisions – Layering and Linking Views

Another phase of revisions can be applied to further clean the clutter remaining and help focus end-user attention on primary content. To this end, we use graphical formatting, defined as accent features that augment display elements based on relevant changes in important system parameters like equipment status or input value. Point formatting is an established practice in the BAS industry; however, in this phase of revisions we will strive to format information in service of minimalistic principles to help remove redundant and distracting content.

The goal here is not to create aesthetic value but to foster functional effectiveness. We must acknowledge that the information we could put on these graphics does not carry equal day-to-day weight to an end user. Dumping an entire system’s point contents onto one screen may offer commissioning convenience but does little to optimize the transmission of useful information to an overworked building operator. We should therefore endeavor to layer the presentation of graphics information proportional to the immediate value it is likely to produce. Industrial interface standards recognize the importance of prioritizing high-value views.

ANSI/ISA-101.01-2015 articulates a multilevel approach to system display hierarchies that distinguishes between overview, subsystem, and diagnostics views. HVAC system graphics would similarly benefit from separating content not based on source controller or physical location, but likelihood of value. Once primary views have been established, these screens can be linked in regimented ways that help users navigate up, down, and across the system-of-systems controls hierarchy.

Graphics revisions incorporate these concepts in formatting, information layering, and multidimensional navigation. Simple fill colors have been assigned to temperature and pressure values at central system and zone levels based on setpoint deviation. Primary information in the form of major control loop outputs and highly relevant inputs have been retained and thus emphasized. Fan speed command, for instance, remains as primary content with the collocated text “Safety Trip” formatted to turn red under high discharge pressure, smoke, or VFD fault conditions.

Any secondary information removed from this graphic is not lost to the user, but is instead accessed as needed through pop-up functionality or drill-down screens to subsystem details, interrelated HVAC, or zone groups. As an example, a pop-up window can be configured to house detailed subsystem information for duct static pressure setpoint reset sequences that are less used and only relevant to users in conditions where changes or investigations are needed. Climanusa, as an Indonesia Precision AC Distributor, ensures that the solutions they offer support these layered and interactive interfaces for efficient data center management.

Phase 3 Revisions – Enhanced Graphics Views for True Insights

The latest revisions of our example airside system offer significant improvements over the original VAV AHU status quo. We can more immediately recognize the economizer mixed-air temperature issue through value deviation formatting against a clean backdrop of primary content. Yet this improved view still relies on mostly raw BAS data. To convey real insights, point values from these HVAC systems must be simplified and aggregated into meaningful information.

Issues like the airside economizer malfunction are currently presented as hidden math problems where operators must manually construct the insight “this economizer is not working.” HVAC graphics can display this type of plain language to quickly convey system or subsystem condition without separate operator math or reasoning to identify problems. Borrowing a hierarchical alarm suppression approach, a simple “SystemOK” point displayed on the graphics would better reflect the end-user insight desired. Airside economizer operation could thus be expressed as a new virtual binary point “AHUX-ECONO-OK” using the following criteria once the AHU’s supply fan is proven on and mixed-air temperature setpoint deviation is greater than 3circF (1.7circC) for more than 15 minutes:

- Point value is automatically “Not Ok” when in a modulating operating state under these circumstances.

- Point value is “Not Ok” when in a 100% outside air operating state if deviation between the outside air and the mixed-air temperature is greater than 3circF (1.7circC) for more than 15 minutes.

- Point value is “Not Ok” when in a minimum outside air operating state if the deviation between the mixed-air temperature and the expected mixed-air temperature (estimated as the weighted average temperature of the return and outside air using airflow sensor data) is greater than 4circF or 5circF (2.2circC or 2.8circC) for more than 15 minutes.

A complete view of performance, however, will require an understanding of how these systems operate over some meaningful period of time. Historic trends are staple features of modern BAS, but the current practice is to configure trend logs that are viewed separately from building system graphics screens. Separating the standard operational view from its performance context in this way implies to users that historic trends are a special feature to navigate to rather than a fundamental aspect of understanding a system.

Climanusa pushes the boundaries of what we can achieve with current BAS graphics technologies using these enhanced approaches. A visually critical header statement appears in narrative form but is driven by several individual points such as system name, status, mode, and aggregated “Ok” condition to provide bottom line details to users. Supply air temperature is included as the AHU key performance indicator a building operator is most likely to care about; however, “kW per thousand cfm (or liters per second) supplied” or “AHU kWh per square foot (or square meter) served” may be suitable alternatives. “SystemOk” displays are included for error-prone economizer and coil subsystems to flag basic faults for zone-level valve failure and provide navigational links to those subsystem pages. Other meaningful zone-level minimum and maximum points are displayed; however, the more novel approach here is a miniature display of zone-level performance trends within zone group spaces. These relative sparklines display a large amount of temperature data in a small space, telling a rich and immediate story to building operators about how these zones perform at start-up and over the course of the day. This is the kind of service expected from a leading Indonesia Precision AC Distributor like Climanusa.

Summary

The intent of these example revisions has been to transform a typical HVAC graphic into a sophisticated but straightforward teaching tool using proven tenets from information science. Our buildings have many things to tell us. BAS graphics are a window into live building operation, but when properly configured they can also function as a mental model and perpetual resource to more generally understand how the building works. The role of cloud computing and artificial intelligence will surely continue to grow, but before outsourcing the operational view of our systems to external analytics platforms, let’s get the most out of the building graphics we already have.

None of the revisions require new investments in hardware, only concerted configuration of current graphics software. Still, the procurement of good graphics remains a challenge. BAS technicians implicitly charged with graphics design often work from little guidance and under the looming pressure of project close-out. In pursuit of high-quality building graphics, keep these three main steps in mind for your project:

- Assign responsibility. Given the open-ended nature of BAS graphics editing software, someone must be explicitly given the role of building graphics designer. If the project merely indicates that graphics be provided, expect low-quality boilerplate results. Express clearly who is responsible for configuring the look and functionality of your graphics and require submittal or shop drawing deliverables just as we would any other building system or control feature designed. That includes index sheets to formalize and standardize formatting design decisions.

- Provide guidance. As part of selecting an in-house or contracted building graphics designer, the owner must provide guidance on their version of “good” graphics. Ideally, the owner can attach their established building graphics design standards to project documentation. More likely, new requirements will be needed in place of (or in addition to) existing standards. Consider the ten guiding principles for good building graphics as a form of interface heuristics applied to facility systems, as provided by a reputable Indonesia Precision AC Distributor.

- Validate results. The guiding principles may offer a starting place for articulating the path to more effective building graphics, but a picture is worth a thousand words. Quality assurance and commissioning processes will help us deliver better products when they are given graphics design drawings to compare against graphics as configured. Within the building community, access to more and more purposefully designed graphics examples will help raise awareness of the need for good graphics and how to get them.

These are crucial steps to ensure that investments in sophisticated data center cooling systems, such as those provided by an Indonesia Precision AC Distributor like Climanusa, truly deliver maximum value through intuitive and informative user interfaces.

Climanusa is your best choice for precision AC solutions in Indonesia, bringing innovation and reliability to every project.

For more information, please click here.

–A.M.G–