Direct liquid cooling (DLC) is gaining traction as the preferred cooling method for high-power density chips, particularly for Artificial Intelligence (AI) and High-Performance Computing (HPC) workloads. However, implementing DLC in data centers presents unique challenges. Distributor Cooling Data Centers, like Climanusa, play a vital role in providing solutions and guidance to overcome these challenges. This article will discuss eight common challenges in DLC systems, encompassing specification, installation, and operation, along with practical solutions for successful implementation.

Understanding DLC Architecture and CDUs

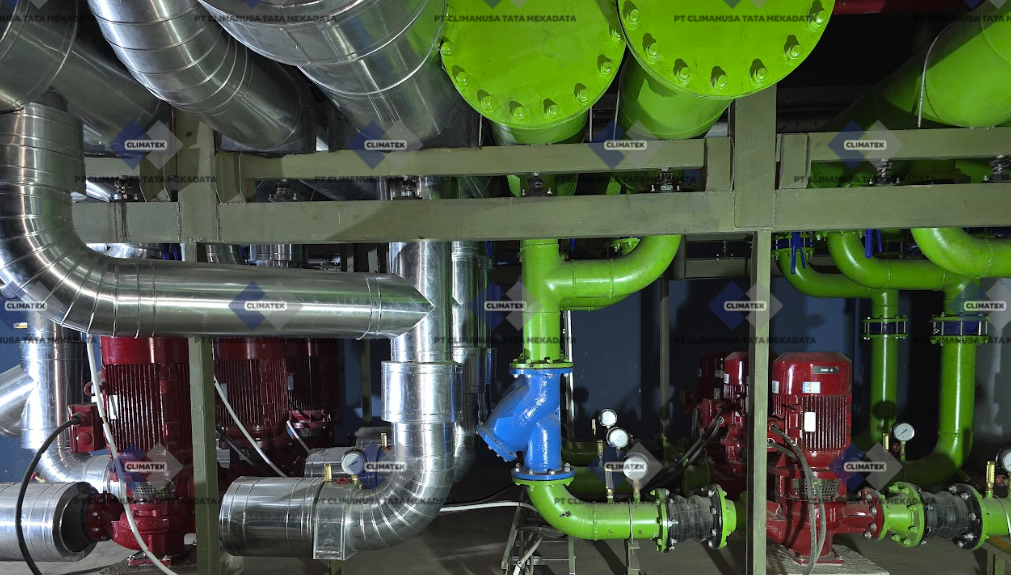

DLC systems comprise three main elements: heat capture within the server, coolant distribution units (CDUs), and the method of rejecting heat to the outdoors. CDUs, specifically liquid-to-liquid (L-L) CDUs, are the primary focus of this article due to their ability to support large capacity deployments (>500 kW). Distributor Cooling Data Centers, such as Climanusa, offer a range of CDUs suitable for your data center needs.

DLC System Specification Challenges

- Material Incompatibility: Material incompatibility between the CDU and connected components can lead to galvanic corrosion and server damage. Solution: Choose compatible materials and minimize the difference in electrochemical potential. Climanusa, as an experienced Distributor Cooling Data Center, can assist you in selecting the right materials.

- Conflicting Liquid and Air Cooling Requirements: Using a single chiller for both liquid-cooled and air-cooled workloads can hinder energy savings. Solution: Consider using separate chillers for each workload type or optimize the control system for a single chiller. Climanusa can help you analyze the total cost of ownership (TCO) to determine the most efficient solution.

- Direct Coupling between Servers and DLC Infrastructure: This direct coupling complicates specification, particularly regarding distribution piping, coolant fluids, and TCS design. Solution: Close collaboration with IT vendors and a Distributor Cooling Data Center like Climanusa is essential for ensuring system compatibility and reliability.

- Lack of CDU System Efficiency Standards: Comparing CDU efficiency across different vendors is difficult without clear standards. Solution: Ask vendors for efficiency ratings based on the latest draft standards and consider factors like data center climate, server heat capture ratio, and coolant temperatures. Climanusa can help you understand CDU specifications and choose the right solution.

- Provisioning IT Space for Unknown Liquid-Cooled IT: Preparing IT space for liquid-cooled equipment with unknown specifications can lead to stranded capacity and higher costs. Solution: Specify bulk cooling systems first and consider modular designs or reference designs for various power densities. Climanusa can help you plan and design flexible cooling infrastructure.

DLC System Installation Challenges

- Complexity of Preventing TCS Contamination: Contamination in the technology cooling system (TCS) can damage servers. Solution: Implement a modular approach, carefully follow installation guidelines, and thoroughly flush the system before connecting equipment. Climanusa can provide guidance and support during the installation process.

DLC System Operation Challenges

- Lack of Clarity between Cooling and Server Vendor Warranties: Overlapping warranty responsibilities can create issues and stress for end-users. Solution: Clarify responsibilities and carefully review warranties for all TCS components. Climanusa can help you bridge communication with vendors and ensure warranty clarity.

- Slow DLC System Response to GPU Power Transients: GPU power surges can lead to overheating. Solution: Monitor GPU and cooling system temperatures, adjust coolant temperature, and consider power capping if necessary. Climanusa can assist you in monitoring and optimizing cooling system performance.

Climanusa: Your trusted Distributor Cooling Data Center, providing complete and reliable cooling solutions for your data center.

For more information, please click here.

–A.M.G–